- June 2017

- President’s Notes

- ASI Submits Nominees for ALB, NSIIC

- Industry Sets Research Priorities

- Photo Contest Now Open

- Vermont Natural Lamb

- Opportunities to Expand

- Let’s Grow Supports Education

- Let’s Grow Awards Round Five Grants

- NSIP Certification Launches

- ASI Represents Industry at IWTO

- Market Report

- California Ram Sale a Success

- Nasal Swabs Needed for Research

- The Last Word

NSIP Certification Launches

TERRI QUECK-MATZIE

Special to the Sheep Industry News

In 1986, the National Sheep Improvement Program – secure in the knowledge that quantitative genetic selection works – began its efforts to collect pedigree and performance data and create a database of Estimated Breeding Values. Other segments of the livestock industry, such as beef and swine, had proven the theory and approach.

Yet, only a small number of early adopter seedstock producers subscribed to the program. Others relied on their own in-house systems of genetic tracking. Others, still, resorted to visual assessment of desired breeding stock.

Yet, only a small number of early adopter seedstock producers subscribed to the program. Others relied on their own in-house systems of genetic tracking. Others, still, resorted to visual assessment of desired breeding stock.

That changed in 2013 when the Sheep Industry Roadmap identified quantitative genetic selection as a priority, and the push to bring the entire industry on board began. With funding from ASI, the Let’s Grow Program and the American Lamb Board, NSIP began in earnest to spread its message and method.

“The main breeds that have used the technology effectively have made considerable commercially relevant progress,” says NSIP Program Director Rusty Burgett, citing 10 years of data from NSIP-adopting breeds to prove the point.

During the last decade, the Polypay breed has increased total weight of lambs weaned per ewe by 10 pounds. The Suffolk breed has increased market weight by 5 pounds, while increasing loin eye area and decreasing fat. The Targhee breed has increased total weight of lamb and wool produced per ewe by 10 pounds, while maintaining wool quality. And the Katahdin breed has increased total weight of lambs weaned per ewe by more than six pounds, while increasing internal parasite resistance.

In addition, a 2016 study conducted in Utah by the Leading Edge Sheep Production Group, proved NSIP-sired lambs weighed an average of 3 lbs. per lamb more at market.

“Enhancing the genetic potential of an animal is the foundation for improvement in productivity,” says Burgett. “We want to help create market demand by improving lamb and wool consistency, quality and quantity.”

That includes using terminal sires selected for carcass merit to produce lambs with specific product characteristics such as lean meat at an accelerated rate of gain, as well as maternal sires to raise those lambs and shear a premium wool clip.

“It also means improving industry collaboration by aligning seedstock providers with the needs of commercial producers and lamb feeders to assure all lambs entering the production chain have the genetic potential to produce a high-quality product,” he adds.

To facilitate that goal, NSIP is ready for the next step – a certification program that will allow all segments of the industry to have increased confidence when purchasing feeder and market animals bred based on NSIP Estimated Breeding Values.

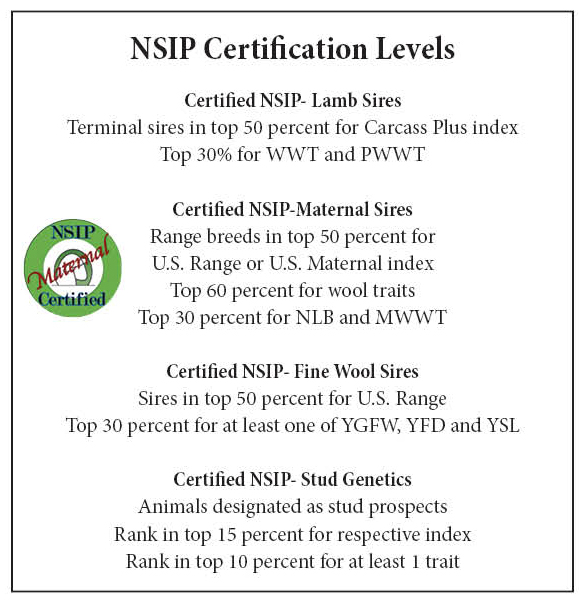

The Certified NSIP Lamb Sires, Certified NSIP Maternal Sires, and Certified NSIP Fine Wool Sires programs are the result of a needs assessment study conducted by Demeter Communications, also funded by the American Lamb Board. The certification program’s main focus is to improve utilization of EBVs in the commercial sector, and then pass those benefits onto feeders and packers.

“The designation offers commercial producers an additional marketing strategy for their feeder lambs, as well as added confidence when purchasing breeding stock with the ability to increase their productivity,” says Burgett.

This first of its kind initiative for NSIP includes a logo to help producers readily identify animals bred with EBVs.

“This logo will tell seedstock, market lamb, and wool buyers that these animals were bred with performance in mind,” says Burgett. “It’s a quick, visual credential that helps all segments of the industry know this animal meets the certification quality criteria.”

NSIP’s plan also includes an educational component. Information will be presented to commercial producers, followed with heavy educational emphasis to feeders and packers. Based on previous participation in workshops and training sessions, Burgett says NSIP plans to reach around 400 commercially oriented producers with the message.

Members of the Fine Wool Consortium and the Leading Edge Production Group will also be trained in program details to help spread the information to their customers and others throughout the industry.